Order Fulfillment Process

What is Order Fulfillment Process?

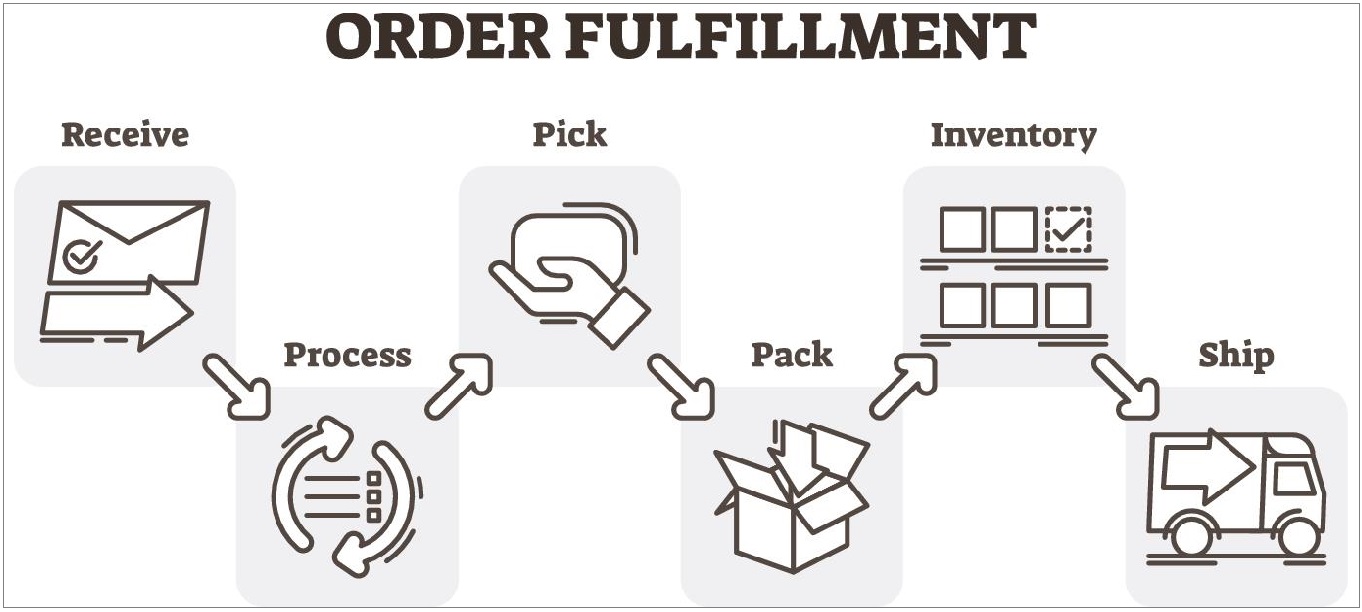

Order fulfillment is the complete process from when an order is placed, or a sale takes place all the way to the customer receiving the delivery. A successful order fulfillment process relies on a third party logistics company (3PL) or a fulfillment center to complete all of the steps required. These steps include receiving inventory, processing orders, picking, packing and shipping an online order to the customer.

What Does the Fulfillment Process Look Like?

There are many steps in the order fulfillment process and they are listed below:

Let Spectra simplify your fulfillment services today!

Receiving

- The first step in order fulfillment is to receive the inventory from suppliers.

Storing Inventory

- Inventory is stored based on assigned locations in the warehouse. Organization is key as it plays a vital role in speed and efficiency.

Order Processing

- Order processing starts once the order is placed. The requested items are picked and packed according to each individual order.

Item Packing

- Items are packed with the appropriate packing materials to ensure the safety of all items shipped. Shipping labels are then placed on each package for shipping.

Delivery of Products

- Most fulfillment companies will offer shipping through FedEx, UPS or USPS. Tracking information for all shipments is provided.

Managing Returns and Refunds

- Most fulfillment companies will handle returns and refunds based on your supplied business rules.

Step by Step Order Fulfillment Process

Are you new to the B2B Ecommerce industry and exploring solutions to move your product as efficiently as possible? Read our step-by-step fulfillment process to learn about the process of receiving goods, then processing and delivering orders to customers.

We offer the perfect solution to fulfillment, with warehousing and distribution of your product. Fulfillment service providers handle all of these things under one roof! Spectra handles everything from receiving your inventory to distribution. As a B2B Ecommerce business, having someone you can rely on to handle the complexities of warehousing and fulfillment is vital. By partnering with Spectra, you save a LOT of money and precious time.

Let’s unbox, unpack, and dig in to find out what a B2B Ecommerce fulfillment service is and the details that go into such a service.

Table of Contents

- Fulfillment Service – Overview

- Customer Inventory Arrival

- Customer Inventory Inspection

- Warehouse Space

- Order Receipt

- Customer Notification

- Picking and Packing

- Shipment

- Inventory Reconciliation

- Delivery of Order

- Returns Management

- HIPAA Compliance

- How a Fulfillment Service Benefits Your Business

- One Solution

- Your Takeaway

Fulfillment Service

Fulfillment services not only include a location for your inventory, but provide the personnel to manage and process orders that get sent out to businesses. Business to Business fulfillment, also known as B2B, refers to shipping in bulk supply for businesses. Businesses that require this service often purchase products in advance, so they don’t have to buy items on a daily basis. They may also supply merchandise to another company for resale purposes.

Fulfillment services are the background mechanics that handle all of the logistical complexities that can easily consume a business owner who needs to get their product managed and shipped.

Accepts Arrival of Your Product

- Inspects the entire inventory for possible damage and quantity count.

- Forwards a report to you of the inventory.

Warehouses Your Product

- Once the new inventory arrives, it will be placed in an area that has specific square footage designated for you.

- Your inventory remains in an environment that is protected and climate-controlled and sprinklered.

- Personnel are on duty to ensure safety, cleanliness, and other protocols are enforced.

Order Management

- Upon receipt of orders, personnel will pick, pack, and ship the product to the business who ordered it.

- The business customer will receive a notification of order shipment.

Returns Management

- Personnel will handle any issues regarding returns on the order.

Real-Time Inventory

- Inventory technology delivers inventory data to you.

Step #1: Customer Inventory Arrival at the Warehouse

At Spectra, WE SEE SOLUTIONS! Let us help you with your fulfillment needs.

Upon receipt of your inventory at the warehouse, personnel receive your inventory into the inventory management system.

- The inventory management system is hosted through SaaS Cloud software.

- This technology provides you with real-time data notifying you of inventory arrival. You can customize notifications of your inventory status, which includes shipping confirmations, understock alerts, zero availability, and inventory availability.

- The cost of this technology is scaled based on your needs and volume.

Once you have partnered with Spectra for fulfillment services, you will have your product shipped directly to our warehouse, where it will be housed, packaged, and shipped to your business customer. Upon arrival at the warehouse, your new inventory is inspected by our warehouse personnel where it will undergo inventory intake.

Step #2: Inventory Inspection

Spectra is ready to take your orders and handle all of your fulfillment service center needs.

Your inventory undergoes a thorough inspection:

- Evidence of any damage

- Comparison to packing slip

- Efficiency, speed, and accuracy are vital at this stage.

- The inventory is carefully handled.

- Inventory inspection is a required practice under our standard operating procedures.

- The inventory management system is initiated/updated.

The inventory is matched carefully to the packing slip and then inspected for any damage. Once inspected and the inventory summary has been completed, your inventory will then be moved into a designated space within the warehouse. Personnel will select either bins or pallets for your inventory to optimize efficiency with quick access. That area becomes your product’s “base camp.”

Step #3: Warehouse Space

Let us keep your inventory organized, on hand and ready for shipping.

The amount of space your inventory requires is scaled based upon your needs.

- Costs of this space are not fixed but rather scaled.

- Personnel, fulfillment, and the technology to process your orders is included, regardless of seasonal demand.

- The warehouse is set up to provide flexible space.

- Storage space is either bins or pallets and is scaled based on the number of SKUs the inventory management system generates.

Having a fulfillment service that you can trust is important. You have a rather hefty investment that you must entrust them with when it comes to not only warehousing your product but protecting it through every step of the fulfillment process. Your business is dependent upon that service to get your product into the hands of the business customer in such a way that imparts a positive reflection on you.

A reputable fulfillment service will provide you with full transparency of not only their processes but also the location itself. Being able to see where your product is stored and managed provides you with peace of mind. The last thing you want to discover is that the items you procured are housed in a building that fails to safeguard your interests.

Things a Fulfillment Service Provider Provides in Warehousing

- Protection for Products

- Effective Management

- Technology

- Ample Space

- Safety Measures

Protection for Products

You are literally handing over thousands upon thousands of your business dollars to a fulfillment company. When it comes to the storing and managing of your product, there’s no such thing as “wiggle room” in protecting the contents of your inventory.

Spectra ensures that all bases are covered when it comes to safeguarding your inventory. We cover all of the below whereas, many warehouses do not.

Outage Contingencies

- Security systems that aren’t backed up with an additional power source leave the warehouse vulnerable to burglary or breach of data.

- An outage can be costly when contingency plans are not in place.

Weather-Related Contingencies

We have no control over what Mother Nature dishes out. Catastrophic events (high winds, tornado, flood, earthquake, etc.) can cause damage to the integrity of the warehouse and/or warehouse infrastructure. When this happens, a contingency plan should be in place to mitigate the damage as quickly as possible.

Flooding Contingencies

Faulty plumbing can cause significant damage to the interior of a warehouse. Preventative measures should be in place, such as automatic shut-off valves and a security system that alerts personnel to a problem.

Fire Contingencies

Fire is a structure’s worst enemy, especially for a full warehouse. Preventative measures must be in place and should never be absent or compromised.

- Automated fire sprinkler system

- Security system that alerts authorities as well as personnel

- Fire extinguishers strategically placed throughout the warehouse

Theft/Vandalism Prevention and Monitoring

A security system will help in monitoring the warehouse 24/7. Every warehouse should have one. In the event of a break-in, the security system should alert the local authorities.

Warehouse Management

Spectra provides you with all of the below for managing every detail that goes into warehouse operations. Some warehouses have significant deficits in warehouse management.

A warehouse cannot be successfully managed without necessary guidelines and standard operating procedures in place. For your product to be protected and to flawlessly flow through the fulfillment journey, robust management is the key to keeping things operating efficiently and safely.

Proactive management includes regular audits and inspections of security protocols. All incoming inventory should be thoroughly inspected, inventoried, and compared to each packing slip.

Technology

A fulfillment service relies on technology and automation for an overall efficient operation. This technology also provides a barrier of protection for your product by keeping real-time inventory.

Ample Space

The last thing you want to do is have your product warehoused in a structure that’s bursting at the seams because of overcrowded, unorganized inventory. Fulfillment service warehouses should provide you with ample space for your inventory. That space should also be scalable in either bin or pallet storage.

Safety Measures

Warehouse personnel should be stringently trained on safety guidelines that protect them, other personnel, and your product. Safety guidelines should include preventing accidents, monitoring for dangerous situations, fire drills, plans in the event of an emergency, COVID-19 protocols, etc.

Step #4: Order Receipt

Once we receive your order, the wheels start to turn in the process of fulfillment.

- Your order initiates the inventory management system.

- We don’t rely on a generic procedure. Labor and pricing is scalable based on your needs.

- Order archival is included to provide you, us, and your historical customer data that can be valuable in liable situations.

- Your marketing efforts benefit from the order archival with insight on reorder needs.

Spectra has a robust order management system (OMS) in place. This system keeps everything moving smoothly, efficiently, and accurately.

We employ state-of-the-art technology, which is the heartbeat of the fulfillment business. Various components of the overall warehouse and fulfillment tasks are controlled by this technology. Tracking inventory provides vital data that is available at the fingertips of both the client and Spectra.

Once a business owner/client initiates an order, it alerts Spectra’s order management system by delivering the scope of the order, sensitivity in shipping time, and other pertinent data that is needed to get a product from the warehouse into the hands of the customer.

Businesses that partner with Spectra have peace of mind in knowing that every order will be processed with the utmost care with attention to detail from start to finish. Orders vary, and because of their uniqueness, tailored solutions are a complimentary amenity in order management. Labor and services are scalable according to customer demand. Through the collaborative effort of Spectra’s team members, the process and flow of orders is seamless and smooth.

Step #5: Customer Notification

Your customer is notified when their order is shipped. Tracking information is included within the notification.

Order shipments are communicated to the shopping cart which prompts shipping notifications to be emailed with shipping details, including tracking numbers, to the customer.

Step #6: Pick and Packing

Spectra offers an array of boxes to make sure that we have the size you need for our next shipment!

Your order is fulfilled through a “pick and pack” process.

- The inventory management system relays real-time data on inventory to avoid low balances, backorders and out of stock situations.

- Every order is picked and packed quickly with a 24-hour (or less) turnaround.

- Orders placed by 2:00 p.m. (EST) are shipped that same day.

- Quality control is employed at every step in picking and packing to ensure the right product is packed in the right box and shipped to the right destination.

- Kitting is customizable and something many of our clients take advantage of.

Quality control is a vital component in this phase of order management. Every detail from the selection of the product, the quantity, and the care given in packaging are scrutinized by personnel. We pay attention to the small details. Simple things such as the positioning of shipping labels all the way to the aesthetics of the packaging are important.

When orders are being filled that involve fragile items, we take extra care to wrap and pad items with protective cushioning to prevent damage during shipping. Specialized handling during packing is a priority.

Piece Pick/Packing

One of the types of fulfillment services that Spectra practices is the “piece” pick/pack method.

- Simple and Straightforward

- Fastest Method

- Better Quality Control

- More Attention to Product Handling

- Less Physically Taxing on Warehouse Personnel

- Geared Towards Small Businesses

“Piece” picking and packing is a fairly simple process. Piece picking is when an employee/picker handpicks each product for an entire order. Items are picked individually, rather than by the case or pallet. This is also known as single order picking. Warehouses/fulfillment services providers usually employ this method for smaller orders. Warehouse personnel are given a fulfillment list which they use to gather product from floor inventory. Each order is given individual attention in picking and packing while ensuring quality control is maintained from start to finish.

Batch Pick/Packing

- More Complex

- Picking Items for Multiple Orders

- Travel Time is Reduced

- Human Error a Possibility

- Order Management Systems Help Reduce the Chance of Errors

The picking and packing method begins to grow more complex at this point. Warehouse personnel are picking items for multiple orders at the same time by grouping orders into small batches. This method not only requires attention to detail, but the ability of personnel to multi-task by pulling product inventory in various zones for multiple business customers. Accuracy can begin to waiver with the possibility of mixing orders. The use of an order management system (OMS) can help reduce the likelihood of order-mixing.

Zone Pick/Packing

- Complexity is less than “batch” yet more than “piece”

- Speed is Slower

- Requires More Warehouse Personnel Strategically Placed on Warehouse Floor

- Less Foot Traffic Per Personnel

- Order Lists Pass Through Several Hands

Warehouse personnel are assigned specific zones on the warehouse floor in which they are responsible for pulling and packing product inventory in their zone. If an order requires product from multiple zones, warehouse personnel will hand off the order/order list to the next zone team member to fulfill their zone’s order list. The “zone” method decreases the amount of foot traffic personnel must make.

Wave Pick/Packing

- Very complex

- Similar to the “zone” method but on a bigger scale

- Speed is dependent upon efficiency of warehouse personnel picking

- Many moving components of this method

- Warehouse fulfillment center personnel are strategically placed on warehouse floor

- Multiple order handling per person/personnel

- Consolidation process must be handled carefully to avoid errors

Like the “zone” method, “wave picking” involves multiple orders being grouped into small batches or waves. Personnel pick items for all orders for each wave by using a consolidated pick list. Warehouse personnel are placed in larger zones, and instead of handling one order, they are responsible for multiple orders. This method offers a shorter cycle time by reducing the number of trips through the warehouse. To avoid errors, the consolidation process must be handled very carefully.

Amazon’s largest fulfillment center provides a glimpse into the massive complexities of large-scale picking and packing. The center’s located in Nevada, and it’s so large that both humans and artificial intelligence (robots) man the center. The center is as big as 15 football fields and 850,000 square feet. Over 1500 workers man zones where robots drive product bins to them for picking. Once a worker picks the product, they move it on to someone else who packs it. The packer is instructed by technology what size box to choose to pack the item(s) in. The box moves further down the line to shipping where automation directs it into chutes where a label is applied, and the box is sealed. It then travels through more chutes to the proper shipping bay, where it’s loaded into freight trucks.

Kitting Fulfillment Options

Kitting is our specialty and Spectra is here to help you with all of your kitting needs.

We offer “kitting” to provide you with an option to leverage product sales through current trends consumers are devouring. Product bundling provides a solution for consumers who are seeking convenience, variety, and value. A single product holds little attraction. However, when you bundle that product with other items, a consumer is more likely to purchase the bundle.

Step #7: Shipment

As the final part of the fulfillment process, Spectra makes sure your items are shipped in secure packaging and on time!

Once your order has been picked and packed, it moves into the shipping department.

- The inventory management system is updated.

- Shipping is done as expeditiously as possible (distribution speed!)

- Spectra reaches 182 million in the U.S. with a 2-day ground service. 27 million in the U.S. is reachable in just one day! Our average delivery time in the U.S. is about 2.47 days. We are located halfway between New York City and Miami and this makes us a prime location for reaching your customers rapidly.

Various methods of shipping are utilized. This enables us to ship your product in the most efficient, economical, and timely manner. Having the right technology in place enables us to quickly find the best shipment method.

Location of a fulfillment service provider plays a big role in how quickly your business customer receives their order. It isn’t logical or economical for you to have a fulfillment service provider on the west coast when the bulk of your customers are located in the eastern region of the U.S.

Shipping Method Selection Considerations

We have an arsenal of carriers at our fingertips to ship orders based on size, weight, delivery destination, and shipping speed. Freight shipments are prepared for shipment by using pallets. Smaller shipments are boxed and sent out via the carrier of your choice.

Size and Weight

Heavy/Bulk Shipments

Some shipping carriers have limitations on the size and weight of shipments. Fulfillment services sending out high-volume, palletized orders typically use a freight carrier because the cost is much lower.

Smaller Shipments

Smaller scale shipments are typically boxed and are shipped using a carrier such as USPS, UPS or FedEx.

Destination

Shipments going outside the country must be handled by an international carrier. International shipping is more expensive in comparison to domestic shipments. Domestic carriers include USPS, UPS, and FedEx.

Special Handling

Shipping orders that are fragile should be sent via a carrier that has reputable fragile handling. Fragile handling will slow down the shipping process, but it protects the product from damage. Shipments containing age-restricted contents (such as wine, tobacco, medication, etc.) require additional handling during shipment to ensure it is accepted/signed by an adult once it arrives at its destination. Fragile or perishable contents will require special handling to prevent damage.

Shipping Speed

Some business customers may need something shipped quicker than others. When this occurs, a carrier must be chosen that will get your product to its destination as quickly as possible. Many business customers are more than willing to pay the extra cost of fast shipping. Carriers used for speedy shipping include UPS and FedEx with overnight or express service.

Overview of Shipping Carriers

USPS (ideal for smaller shipments)

USPS has one of the best options for 2-3 day shipping with USPS Priority Mail. USPS typically offers the lowest rates for packages weighing up to 10 lbs. If a package weighs over 10 lbs, UPS and FedEx offer more competitive rates. It’s important to note that USPS offers no services with guaranteed 2-day delivery. Any packages that must arrive in 2 days work best through FedEx 2 Day or UPS 2nd Day.

- Priority: 1-3 days

- 70 lbs or less

- Priority Express: overnight – 2 days

- 70 lbs or less

- Ground: 2-8 days

- 70 lbs or less

FedEx or UPS (ideal for small, medium, and freight shipments)

Next Day/Overnight delivery is where FedEx and UPS start offering competitive rates compared to USPS. With a strong presence throughout the world, FedEx and UPS are best for expedited shipping. Freight options are available for LTL, as well as international shipping.

- FedEx Priority Overnight: next business day by noon

- FedEx First Overnight: next business day by 10am

- FedEx Standard Overnight: next business day by 4:30pm

- FedEx 2 Day AM: two business days by 4:30pm

- FedEx Express Saver: three business days by 4:30pm

- FedEx Ground: 1-5 business days

- UPS Next Day Air: next business day by noon

- UPS Next Day Air Early: next business day by 10am

- UPS Next Day Air Saver: next business day by 4:30pm

- UPS 2nd Day Air: two business days

- UPS 3 Day Select: three business days

- UPS Standard Delivery: 3+ days

(Over 150 lbs)

Domestic

- 1, 2, and 3-Day Express

- Priority

- Economy

International

- Express: 1-5 business days

Step: #8: Inventory Reconciliation

Spectra is ready to receive your inventory and provide you with the fulfillment services that your company needs to be successful.

The inventory management system is continually updating inventory as products move through the fulfillment process. Inventory reconciliation is performed in real-time, providing a report of the current status of inventory levels. This report also provides valuable forecastable metrics.

Spectra safely stores and protects your products within a warehouse. Reliable, current trending technology and automation are key tools to maintain and manage our warehouse inventory.

3PL fulfillment warehousing can prove challenging because of the amount of inventory in constant motion. There are several stages of inventory management. It’s critical that at every stage, an inventory management system provides a real-time update on a business client’s product inventory. Every item should be accounted for regardless of what stage it’s in.

- New incoming inventory (inspected and prepared to place in bins or pallets)

- Currently, in-stock inventory (located in bins or pallets)

- Inventory currently being fulfilled and processed for orders (being picked and packed)

- Inventory that has been shipped to the business customer (tracking information)

Just as in warehousing your product, inventory management is equally important. With the right inventory management strategies and tools, your inventory is protected and accounted for to avoid loss. Again, you must be able to place your complete trust in a fulfillment service to maintain control over every single item in your inventory.

Once orders are placed, our warehouse personnel will begin picking and packing your inventory to prepare it for shipment to your business customer. As inventory begins moving, it’s vital that every item is accounted for. This is accomplished with state-of-the-art technology. At any given time, you should be able to access real-time data of the current quantity of inventory and tracking information once it is shipped. The complex mechanics behind this phase of fulfillment must flow accurately and flawlessly.

Inventory Data is Crucial

With our technology on board, valuable data is produced that is vital for you and us.

- Ensuring you have inventory available at all times and never run out.

- Your inventory doesn’t sit and become outdated.

- Your warehouse storage space is always being optimized, so you don’t pay for more space than you should.

- You gain insight into trends in your product.

- Your marketing can be tailored by understanding those trends.

- Forecasting of your inventory provides you with information to help you leverage future sales.

Step #9: Delivery of Order

Delivery of Order

Regardless of what shipping carrier is selected, a positive delivery experience is something the business customer will be impressed with. 94% of customers who experience poor delivery blame it on the source that sent the order. So, we work closely with the major carriers to make sure that your package arrives on time.

One big benefit of outsourcing fulfillment is that the major carriers pick up orders directly on a daily basis. This ensures that your orders are being shipped in a timely fashion every business day.

Spectra does everything within its power to avoid delivery distress. The customer should never experience their order being delivered to the wrong address, arriving damaged, the wrong product sent, or a delay. We take extra care to pack all items with the appropriate packing materials—making sure that your items are fully protected to withstand the heavy hands of the shipping process.

Step #10: Returns Management

Although Spectra very rarely has any returns, we are ready to mitigate any return issue. We have an impeccable near 100%-free return history!

Returns are something that we strive hard to prevent. However, when and if it should ever happen, we are poised to send out a new order as quickly as possible.

HIPAA Compliance Observance

Spectra is equipped to handle all of your mailing needs and we’re HIPAA compliant to keep your information safe and secure.

Spectra is well versed and experienced with HIPAA standards. Although we are not directly involved with healthcare to which HIPAA is associated with, strict adherence must be maintained at all times when handling data that falls under Protected Health Information (PHI.)

Distributors: 84% Manufacturers: 79%

How a Fulfillment Service Benefits Your Business

Today’s Ecommerce industry is hungry for solutions as demand grows at an increasing speed. The 2019 gross merchandise volume (globally) for B2B Ecommerce skyrocketed! The figures are staggering, to say the least.

2019 – equivalent to $12.2 trillion USD

2013 – equivalent to $5.83 trillion USD

A 6-year increase equivalent to $6.43 trillion USD

Outsourcing order fulfillment has become something businesses are reaching for. Money can be saved by partnering with a fulfillment service provider. Spectra can save you the overhead costs of housing, managing, and fulfilling orders.

Spectra Saves You a Significant Amount of Money

Partnering with Spectra provides you with everything we have outlined and covered in this article. You get ONE SOLUTION that umbrellas MULTIPLE NEEDS!

Let us help you save time and money in warehousing and fulfillment. Searching for a location, visiting the site, and going through the paperwork to rent/buy the warehouse requires a colossal amount of time and money. Once you do procure a warehouse, you must insure it, install the necessary technology to facilitate security, oversee the management of inventory and orders, develop real-time data, handle shipping integration and more. You will then need to invest in the interviewing, hiring, and training of the employees it will take to run the day to day operations of fulfillment. Not to mention the overseeing and maintenance of the warehouse, data, and technology.

Expenses incurred in acquiring your own warehouse

- Rental/purchase of a warehouse

- Maintaining a climate-controlled environment

- Insurance on the warehouse and all contents

- Installation of technology (software, internet, hardware, etc.)

- Equipment to run a warehouse (forklift, conveyor belt, etc.)

- Purchase of supplies

- Developing SOPs, KPIs, marketing plans, websites, etc.

- Personnel

- Warehouse maintenance

- IT technician

- Fulfillment personnel

- Personnel Training

Benefits of Partnering with a Fulfillment Service

- Provides you with warehouse space, labor, security, supplies, technology and management.

- Your product is delivered to the customer in a professional and timely manner.

- Enhances your overall business operation by giving you back the time you need to devote to other areas of your business. Takes a heavy burden off you.

- Provides you with valuable metrics.

- Gives you peace of mind while providing you with superior service that exceeds your expectations.

- Provides you with competitive pricing to effectively manage every phase of fulfillment.

You Get Valuable Data Analytics

- Accuracy

- New inventory

- Existing inventory

- Real-time inventory

- Picking and Packing

- Kitting

- Time it took to fulfill the order

- Shipping

- Customer Notification

- Carrier’s ability to deliver on time

- Tracking

- Carrier’s overall reputation

- Cost efficiency

- Rate of Returns

- Damaged shipment

- Insufficient packing

- Carrier handling

- Incorrect product

- Error in picking and/or packing

- Defective product

- Order Archival

- Provides valuable insight on trends

- Enables customer to replenish

One Easy Solution

Spectra proudly shines with an outstanding reputation for accuracy and attention to detail! Our location provides reachability quickly across the U.S. We are located on the eastern half of the U.S. midway between New York and Miami.

Spectra averages 2.47 days in their delivery time in the U.S.

We offer an ALL-IN-ONE solution for your fulfillment needs. We do it all under one roof with the personnel we are proud to have as part of our team.

The Solution You Need!

- Flexible and scalable warehouse space that’s clean and climate-controlled.

- Technology that provides the innovation to be a top-performing service.

- Real-time inventory management begins the moment your product is received into the Inventory Management System. Every item is accounted for at any given time.

- The moment your product arrives, we carefully inspect it for damage, compare it to the packing slip and then forward a full report to you along with digital images. Most other fulfillment service providers don’t offer their clients this personal touch to give them peace of mind.

- Careful handling of your product.

- Shipping is selected through reputable carriers.

27 million people in the U.S. can be reached in 1 day

182 million people in the U.S. can be reached in just 2 days!

Spectra’s Other Services

- Printing Services

- Small to large jobs

- Print distribution

- Color matching

- Variable data printing

- Security printing

- Specialized options; foil, raised ink, sleeking

- On-demand book printing

- HD quality

- Binding

- Quality finishes

- Book fulfillment direct shipping

- Trade show materials

- Banners and Signage

- Branded promotional products (ink pens, bags, etc.)

- Apparel

- Menus

- Mailing Programs

- Direct mail fulfillment services with VDP (Variable Data Printing)

- Custom Storefront for online order fulfillment

Your Takeaway

The background mechanics of a fulfillment service provider is without question to be appreciated and respected. The complex intricacies are something that many B2B Ecommerce professionals choose to entrust with a third-party logistics provider such as Spectra.

The benefits of outsourcing and partnering with Spectra outweighs trying to assume such a consuming undertaking. You have so much to gain with Spectra’s expertise and so little to lose!

Contact us today, and we will be more than happy to provide you with a quote on getting you closer to optimizing your B2B Ecommerce fulfillment needs!

I’m interested in using your Charleston facility for my ecommerce business. I ship about 500 boxes per month. What is the best way to get a quote from you?

If you can provide us with a Scope of Work, we can give you an estimate on price. You can also give us a call to discuss, we’re more than happy to communicate with you in whatever manner suits you. A phone call is usually best so that we have a chance to fully understand your needs and be able to give you more concrete pricing.

If I decide to use a fulfillment company, is someone going to be responsible for making sure that my products arrive in good condition?

Absolutely! We inspect all products that arrive on a daily basis. If there is any damage at all to any of your products, we will notify you immediately and also send you a picture of the damaged product, if you request one.

My company is looking to add fulfillment services somewhere on the East Coast. We do a lot of business in the Southeastern part of the country and I see that you have two locations in South Carolina. What is your deadline for same day shipping of orders?

Our goal is to pick, pack and ship all packages same day as long as the orders are received by 2pm. The only reason that we wouldn’t meet that deadline is if the order required special packaging or was of excessive volume.

I’m a small business that is just starting up and I would need to deliver my goods to your facility in the Charleston area. Do you allow people to do that, or do you just accept inventory or goods with trucking companies?

No, you don’t have to use a trucking company. You are more than welcome to bring any inventory or goods to the warehouse yourself. We like to get to know our customers.

I have a small company that specializes in technology accessories and the temperature of the storage is very important. Is your warehouse climate controlled?

Yes, it most certainly is. We are a climate controlled facility and we have several clients that we handle technology accessories for. Please don’t hesitate to contact us to discuss how we can help with your fulfillment needs.

Does your Order Management System offer any type of reporting?

Yes, it offers real-time reporting on reports such as understock notifications, zero balance notifications and product summaries to name a few.

Is my customer notified once they place an order using your OMS dashboard system?

Order shipments are communicated through the dashboard which prompts shipping notifications to be emailed with shipping details, including tracking numbers to the customer.

How do you determine how much space I will need for my inventory?

First, we will look at your inventory to determine if you need your items stored in bins or on pallets or both. The warehouse is set up to provide flexible storage space and is scaled based on the number of SKU’s the inventory system generates.

Will my inventory be inspected after it arrives at your warehouse and what happens if there is any damage?

Yes, your inventory will be counted, inspected and received into our inventory management system. If we do come across any damaged items, we will take pictures for documentation so that a claim may be filed for the damaged items.

I work for a large company and sometimes I’m overwhelmed with sourcing products. Do you have anyone on staff that can help me source products?

Yes, we work with Marketing Managers/Procurement Professionals at many different companies and we’re more than happy to help with sourcing products. We are an ASI distributor and we’re able to find thousands of items at reduced costs. Just let us know what you need help with!

How many people can you ship to in two days or less?

We can reach 182 million people with 2-day ground delivery. This includes cities like San Antonio, Chicago, New York City and Miami. We are able to reach 27 million people with 1-day ground delivery.

If my business takes off, sales increase and I need to expand my inventory, how quickly can you accommodate my growth?

Spectra’s Fulfillment Center offers scalable growth and we can accommodate your need for more space within 2-4 business days. You let us know what you have coming and we’ll create the space for any additional inventory.

Do you require a minimum monthly order volume?

No, we understand that some businesses are seasonal and others have certain business cycles. We’re happy to store your items for you until it’s time to start shipping again.

Are you able to handle and ship bulky or heavy items?

Yes we are, and we’ll work with you to make sure we offer the best packaging possible at a very competitive price.

I like to get my products to my customers with a quick turnaround. Do you offer same day order shipping?

Yes, we do. All orders received by 2pm EST will be shipped out the same day.

I’m very picky about how my products are packaged for shipping. Is there any way I can see a sample of my finished kit before it ships?

Absolutely, we work with many companies that require customized kitting and packaging. If you are in the area, we encourage you to visit with our warehouse team and approve the finished packaging, or we’re happy to send you a photo of your customized kit for your approval.

My company is seasonal, so how do you charge me if I sell a lot of product and then my inventory drops drastically for a few months?

We provide scalability with space on a monthly basis. Meaning, we only charge you for the amount of space that you use. If your inventory drops then your cost will as well.

Are you able to provide notecards or some type of printed material with each order?

Yes, we’re happy to use printed materials supplied by you or we can print some for you. We’re also a printing company so we can produce any type of printed material that you’d like. We can even personalize them for each order.

Packaging is very important to me and I like to use different colors of tissue paper. Are you able to accommodate custom kitting orders?

Yes, we can certainly accommodate custom kitting orders, and we do that on a daily basis. We take the time to thoroughly understand each kitting project and we’ll even send you a picture of a sample kit for your approval.

If I were to have my products transported to your warehouse, how do I know that you received all of my items?

All incoming inventory is inspected, inventoried and compared to each packing slip upon arrival. After all products/SKU’s are entered into our Inventory Management System, we’ll provide you with a report of all inventory received, complete with pictures if requested.

I’m very interested in your services and I’d like to know if it’s possible to visit your fulfillment center?

Absolutely, please feel free to contact us and we’ll schedule a tour that is convenient with you.

My company is gift packaging and are you able to store and warehouse prepackaged nuts, coffee and candy?

Yes, we are registered with the FDA for the warehousing and storing of non-perishable food items

If I decide to use your company for fulfillment services, does a representative from our company need to be there when the products arrive?

No, you don’t need a representative present. We will gladly receive all of your inventory, inspect it and enter all products into our Inventory Management System. You will then receive a report listing all items and we will alert you if we find any damage to any of your items.

I’ve reached out to some 3PL’s and they have minimum order volumes. Do you have minimum and maximum order volume requirements?

No, our fulfillment services are based on our customer’s needs. We’re flexible with both space and volume of orders.

If I decide to try your fulfillment services, do I have to sign a long-term contract?

No, we don’t require long-term contracts.

My company has different chains of command with different approval rankings. Do you have the ability to give my procurement staff different views of product and different spending amounts?

Yes, absolutely. We can assign different product views and different budgets to each individual placing orders. You will have an interactive dashboard 24/7 that is populated in real-time as your inventory decreases or increases.

I read your blog and it’s very informative. I’m new to fulfillment and I’m trying to understand how you determine how much warehouse space I’ll need?

We’ll determine the amount and type of space you require by using calculations which include: quantity of inventory, measurements of SKUs, weight and the ability to stack.

I’ve had issues in the past with damaged products arriving at warehouses. What’s your procedure if any of my goods are damaged?

We inspect all inventory that is received at our warehouse. We’ll notify you of any damage to your products with pictures and reporting on unacceptable or damaged goods. We’ll provide you with proof of damage so that you can make a claim with your carrier. If we chose the carrier for your products, then we will make the claim on your behalf.

Do my SKU’s need to have barcodes?

Typically yes, because scanning barcodes of client inventory converts to real-time accounting of your inventory for receiving and shipping purposes.

I’m currently looking for a 3PL provider and I was reading your blog. If we decide to move our inventory to your warehouse, do you come and pick it up or do I have to arrange for transportation?

We’re more than happy to work with you on the logistics. We can recommend some transportation options for you, or we can develop a collaborative plan of action for your inventory to be organized for transport. Whatever works best for you!